Cell Cutting / Laser Direct Cleaving (LDC)

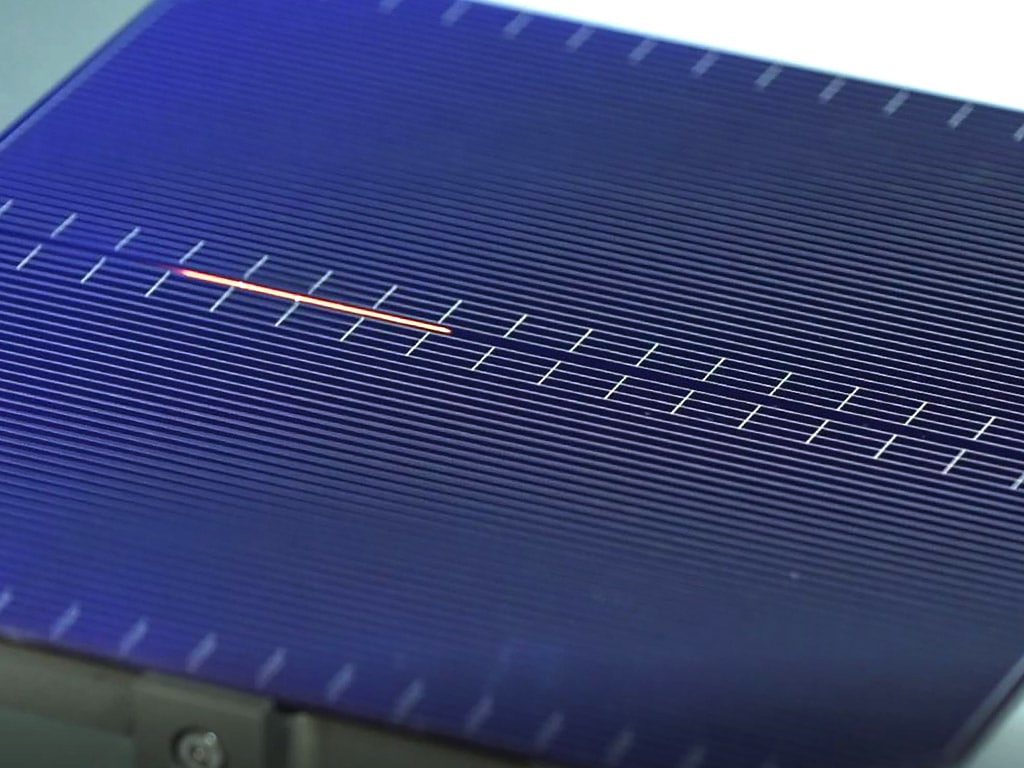

New separation processes for crystalline silicon solar cells keep entering the PV market. One example is the innovative cell cutting technology Laser Direct Cleaving (LDC). InnoLas Solutions’ patented thermal separation process is guided by a laser beam and is a direct gap process.

LDC vs. Scribe and Break

While the cell is ablatively scribed in the traditional “scribe and break” process, the laser takes over the guiding of the break edge in the LDC. The local induced voltage of the laser beam then allows it to be guided along an almost freely definable line to the opposite cell edge. The solar cell is thus split purely by the voltage generated by the laser beam. This is not only particularly gentle on the material, but also eliminates the need for additional cooling media and extraction.

Your advantages

- High speed

- Particle free operation

- No mechanical separation necessary

- Cost savings

- Time saving

- Prevention of microcracks

- Lower cell breakage rate

A look ahead

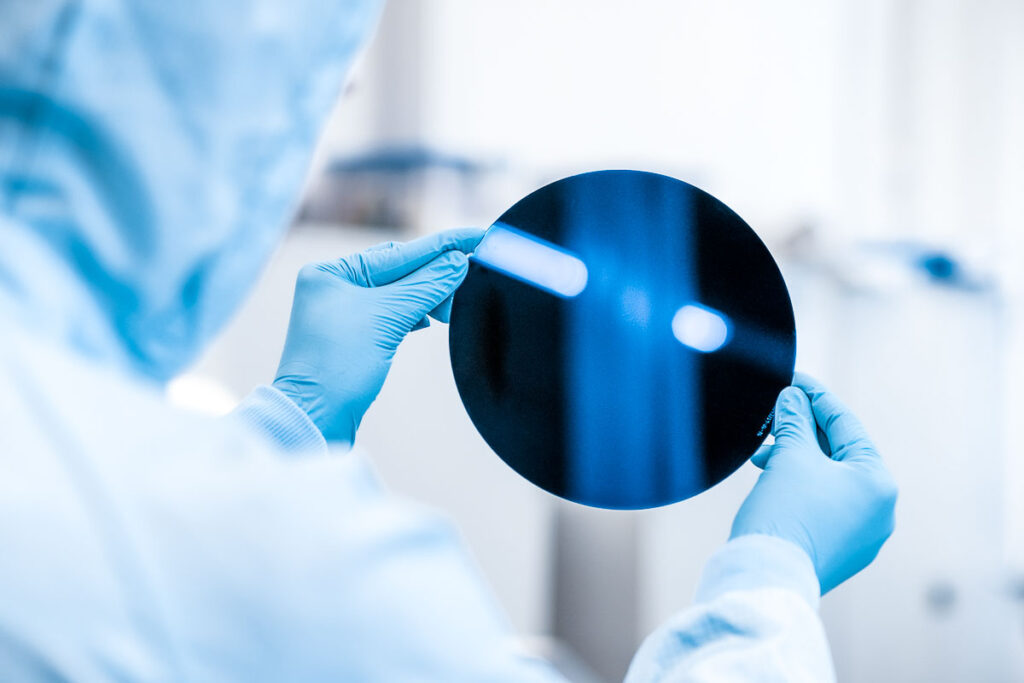

The fully automated cell cutting solution LDC combines a laser slitting process with integrated handling automation. Currently, wafers larger than 158.75 mm pose greater challenges to conventional processes. By means of laser direct cleaving, processing up to a wafer size of 210 mm is possible without any problems and almost without affecting the cycle time.

Recommended machine type: LUMION

The LUMION is a state-of-the-art laser system for processing crystalline solar cells. It achieves a throughput of up to 7,500 wafers per hour and is used 24/7 in industrial production. The LUMION is available for various applications, such as Laser Direct Cleaving (LDC), Passivated Backside Contact Opening (PERC) or for Local Doping (LDSE).