Laser drilling for printed circuit boards with diameters from 15 µm

Flexibility, precision and speed in laser drilling

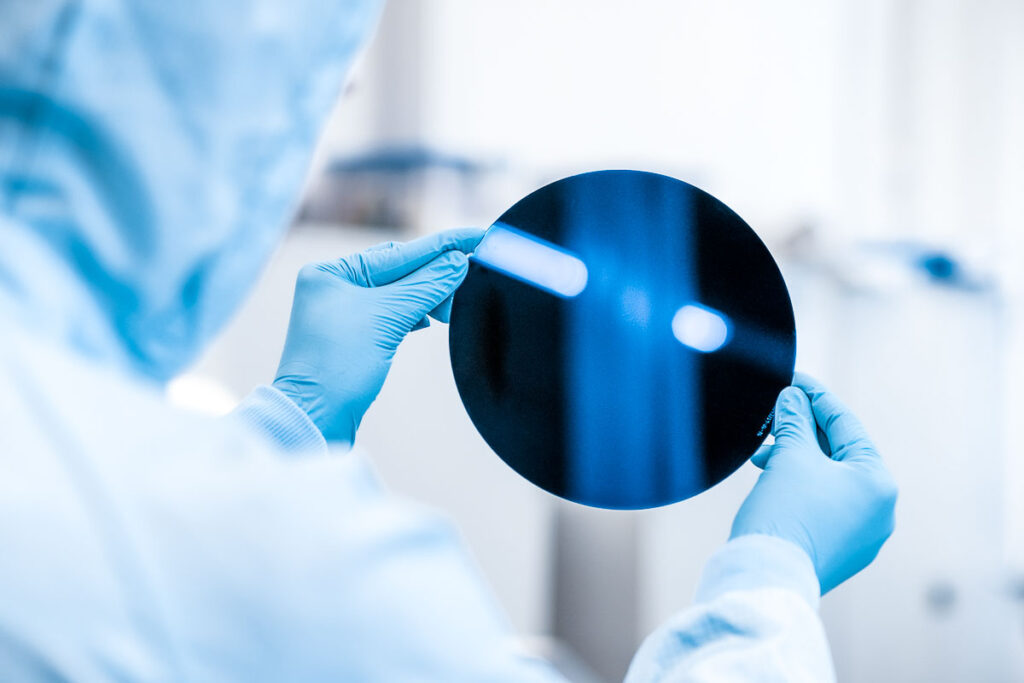

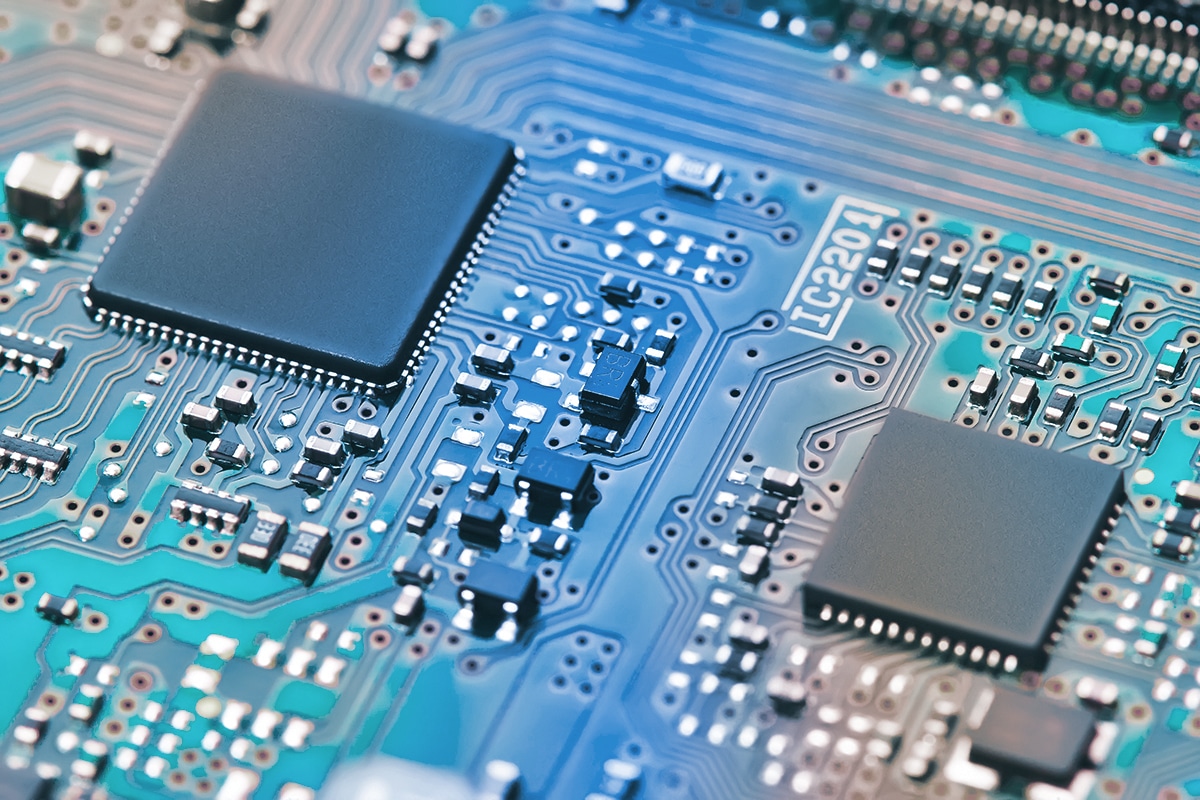

As a specialist in PCB processing, InnoLas Solutions offers individual solutions for drilling blind vias and through holes in rigid and flexible PCBs, among others. Our equipment drills micro vias with high aspect ratios and diameters down to < 15 µm. As a specialist for Trepanning or percussion drilling with ultrashort pulse lasers, we stand for ideal process results in a wide range of PCB materials, such as RCC, FR4, FR5, polyamide, etc.

Laser drilling enables unrivaled level of quality

Whenever mechanical drilling methods reach their limit, it’s time for laser drilling. Lasers not only enable extremely precise drilling, but also previously unattainable levels of quality. In addition, laser drilling is also particularly gentle. Since this is a non-contact process, there is no thermal or mechanical stress on the material. There are no chips either, because the removed material simply evaporates and is completely extracted.

Economical work thanks to laser drilling

However, laser drilling processes not only enable borehole diameters to be achieved that could never be reached with exciting processes, they are also extremely economical to work with. Not only is laser drilling characterized by a higher production speed, it is also more process-reliable than traditional methods and can easily be completely automated with the concepts of InnoLas Solutions.

Advantages of laser drilling compared to conventional drilling method

Cost-effective, precise, fast

Compared to conventional methods of drilling, laser technology offers decisive advantages:

- Non-contact process – no mechanical tool wear and no force applied to the material

- Large process windows in combination with a wear-free tool allow maximum price stability with highest quality

- Minimal heat load – no coolant required, no component damage near the laser processing area

- Freely selectable diameters (via): smallest holes from 15 µm possible even in hard-to-reach areas

- Low maintenance and servicing costs

- No damage to the surface or the underlying layers

- Rework-free precision drilling

- Maximum cleanliness – no chips or dust

- Small hole-to-hole distances can be realized

- Material freedom

- Design freedom

- Process stability

The economical solution from prototype production to large-scale production

Some companies shine through small-scale specialization in very specific components. Although the quantities remain manageable, the work – for example in the manufacture of printed circuit boards – requires the finest vias (“holes”), compliance with the tightest tolerances and reliable reproducibility of the result.

InnoLas Solutions also offers individual solutions for microdrilling by laser for such companies, e.g. the LINEXO linear table machine. This is characterized by compact and flexible design. This makes the LINEXO particularly suitable for small and medium-sized companies in the electronics, semiconductor and photovoltaic industries. The accuracies of our machines is unique with up to 5µm.

Advantages of laser drilling using ultrashort pulse lasers

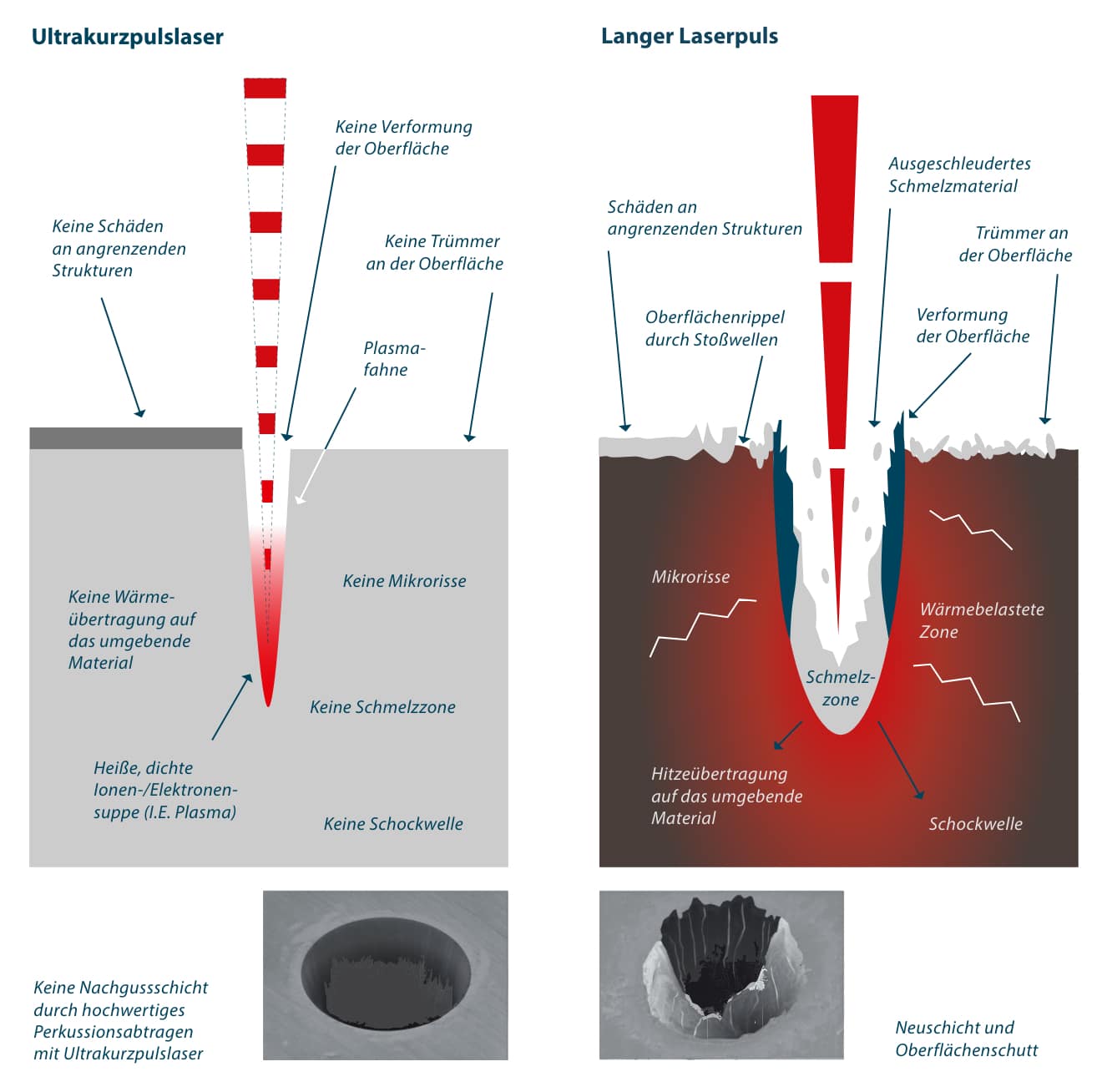

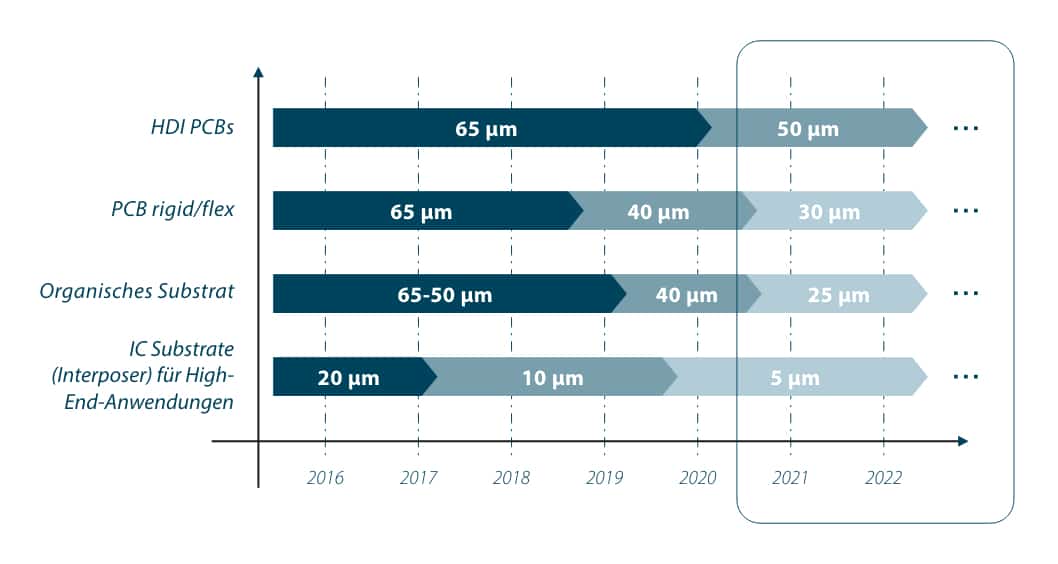

The ultrashort laser pulse is already indispensable for drilling various materials with high aspect ratios. Short pulses enable the smallest vias, which means that smaller electronics can be realized.

Already since the early 2000s, due to the ever-shrinking electronic products, high-power ultrashort pulse lasers have been developed, which enable completely new processing methods with pulse durations in the femto- and picosecond range.

- Strong localization of the energy input

- Targeted use of nonlinear absorption mechanisms enables highly efficient processing of semiconductors and insulators such as silicon, glass, sapphire and ceramics

- No enamel deposits

- Highest process qualities, as material is evaporated and extracted directly

- Low heat losses – far higher lateral resolutions down to the sub-µm range

- Lateral resolution is not directly related to heat losses

- No generation of shock waves

- No micro cracks

- No delamination

- No significant heat input

Laser drilling with laser machines from InnoLas Solutions

InnoLas Solutions is a leading supplier of laser machines for drilling through holes and blind holes and removing cover layer materials.

We supply the right machine for every processing and manufacturing process, for every material and material thickness. A choice of laser options and different system features allows you to find the right balance between cost and quality for your laser drilling applications, depending on the application.

InnoLas Solutions is the right partner for both special applications and large series. We will be happy to support you in selecting the perfect solution for you:

- Laser sources: ultraviolet, green and infrared lasers with pulse durations in the nano-, pico- and femtosecond range

- Degree of automation: Stand alone or as part of a fully integrated production line (Industry 4.0-capable). – Everything from one source!

- Hole sizes:Micro vias with a hole size > 15 µm.

- Aspect ratio(depth to diameter ratio): 1.5 – 2

- Materials: Metals, ceramics, copper in combination with FR4, FR4, FR5, polyamide, etc.

Frequently asked questions about laser drilling of printed circuit boards

What is laser drilling?

In laser drilling, short laser pulses with high power density are fired at a workpiece. The material is ablated in various ways by the energy of the laser radiation, depending on the pulse duration: It is melted, vaporized, or ionized. The greater the energy of a pulse, the more material is ablated. The duration of the individual pulses is decisive for the quality of the bores. Shorter pulse durations significantly reduce the thermal load on the workpiece.

During ablation, the volume of material in the borehole increases abruptly, resulting in high pressure. This pressure drives the melted material out of the borehole within a very short time without leaving any residue.

Alongside laser cutting, laser drilling is one of InnoLas Solutions’ core competencies.

What is meant by percussion drilling?

In percussion drilling, the laser radiation does not hit the material in a long single pulse, but in several short pulses. This causes some material to melt and evaporate each time. The vaporized material thereby tears the molten one out of the borehole with it. Much higher maximum drilling depths are possible with percussion drilling, namely up to 100 mm compared to 2 mm with the single pulse method. In addition, this process is also suitable for machining extremely hard materials.

What is trephining?

During trephination, vias (“holes”) are first drilled using the percussion method. These are then expanded to the desired bore diameter by means of trepanation. For this purpose, a rotating movement of the laser beam in relation to the workpiece is generated. The advantage of this method is the reduced formation of melt layers on the walls of the borehole. This qualifies the process especially for the production of sensitive workpieces.

What are the advantages of laser drilling over conventional methods?

In mechanical drilling, the hole is created by machining using a drilling tool with a defined cutting edge. Chips are produced which can contaminate or even damage the workpiece. The diameter and quality of the hole is linked to the diameter of the drilling tool and its wear, so different drilling tools are needed for different diameters. This requires non-value-added tool changes and, due to the limited tool life, considerable tooling costs. In addition, there is the risk that drills break during an application and the workpiece is destroyed,

Laser-based drilling saves long setup times for changing the drilling tool, and also eliminates tool wear on the drill heads. Ablation of the laser process gives you a residue-free borehole and a chip- and dust-free processing process. Process stability is uniquely high for laser machines because our fully calibrated machines enable absolutely stable process conditions over many years, which can also be directly reproduced on new machines. Accordingly, a process can be qualified in Europe, for example, and transferred directly to production facilities at outsourced locations at the push of a button.

For which applications is laser drilling suitable?

InnoLas Solutions has products and solutions in its portfolio that have the following process capabilities:

Drilling of through holes, drilling of vias (blind holes), removal of cover layer materials.

The high flexibility of our laser drilling systems also comes into its own, especially for small batches!

Is it worth the investment for a laser drilling rig?

Yes, especially since the follow-up costs of conventional drilling rigs and tools (wear, setup times, material scrap, etc.) are eliminated. Laser drilling systems operate wear-neutral, tie up fewer man-hours and increase your added value. Set-up times A clear advantage in competition and in your internal processes. The price/performance ratio of a laser drilling rig today is 10 times better than 10 years ago. This makes these systems economical even for small and medium-sized companies.

What are the advantages of UKP lasers overCO2 lasers

UKP lasers work with pulses in the picosecond range, whereasCO2 lasers work with significantly longer laser pulses. The heat-affected zone of a picosecond laser is much smaller than that of a nanosecond orCO2 laser. The reason: the shorter pulse durations and thus a“colder” ablation. As a result, no particles of solidified melt fall back onto the workpiece or, in other words, with UKP lasers the material is vaporized directly and not melted first as with CO2 lasers. Energy losses in the form of heat are also drastically reduced by direct evaporation, which in turn significantly increases process efficiency.

How small can a laser bore be?

Laser drill holes with an ultrashort pulse laser generally have typical diameters of 20 – 500 µm. Depending on the requirements and the laser drilling method, however, drilling diameters down to 10 µm can be achieved with our systems.