Laser Contact Opening (LCO)

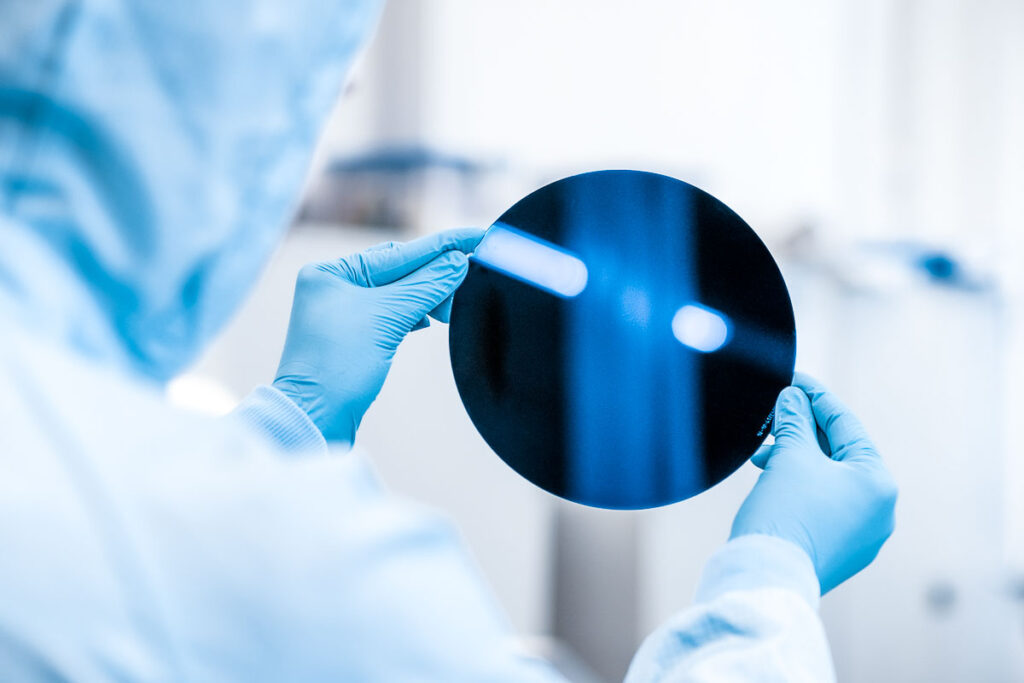

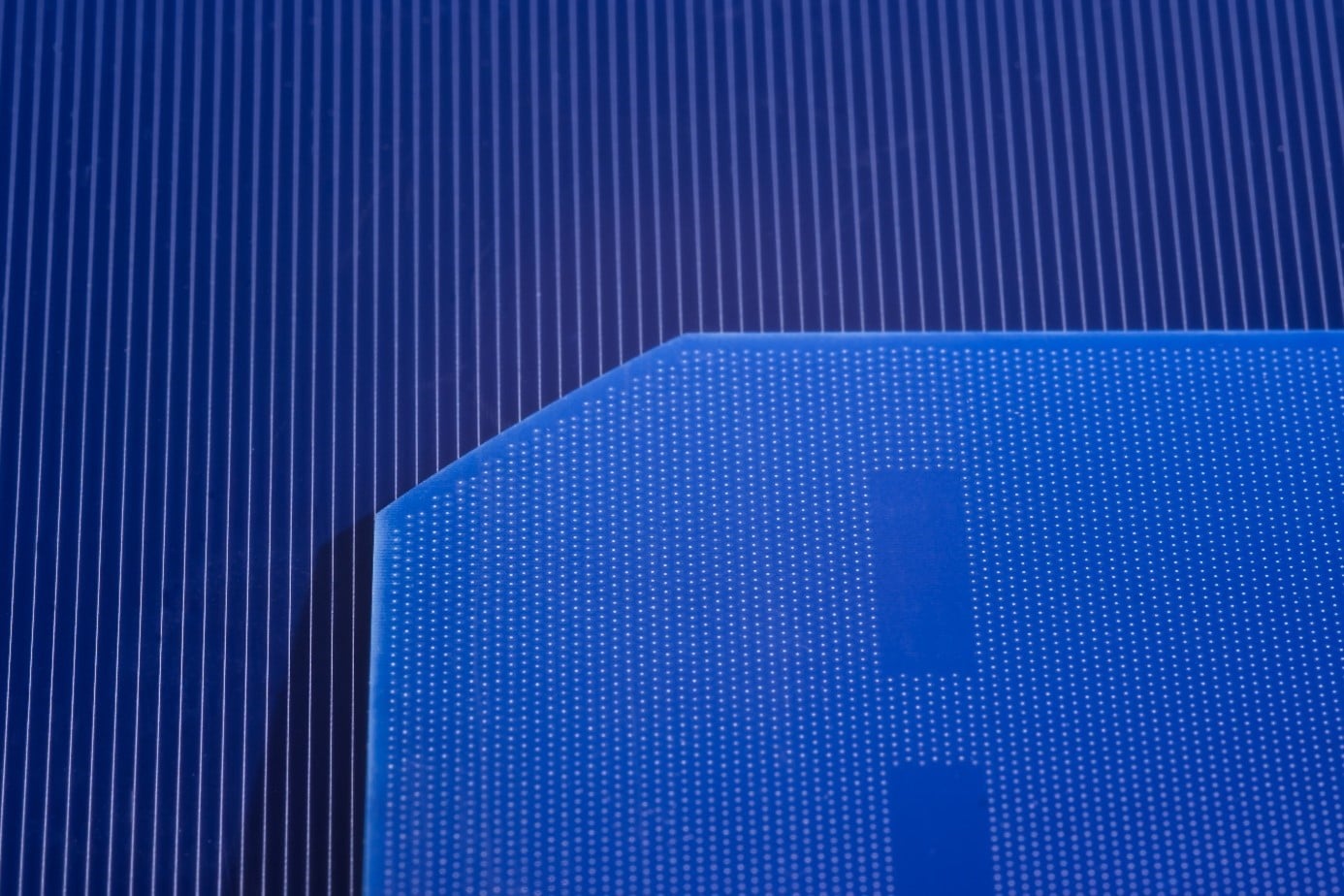

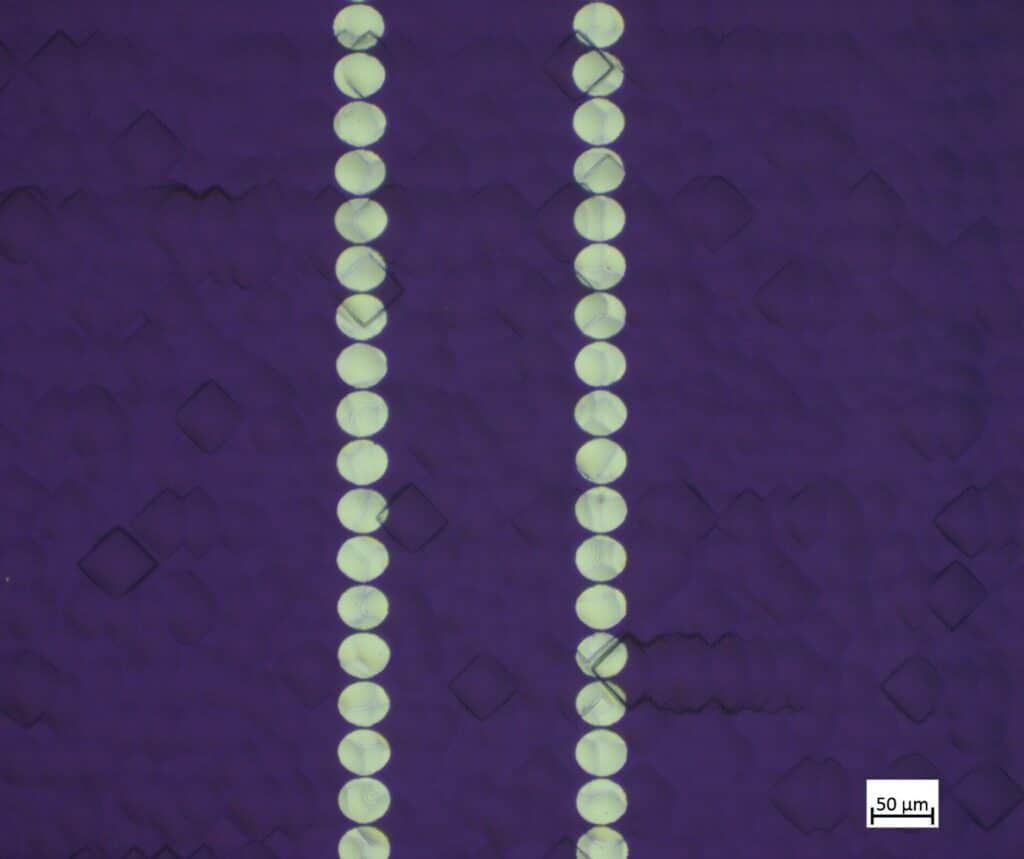

The so-called Laser Contact Opening (LCO) process is an important step in the production of IBC and PERC cells. It creates contact openings at the rear passivation layer by laser ablation. The focus is on selective removal of passivation layers via a dashed, dot or line pattern.

Typical methods for opening the back of the cell

Typical methods for opening the back side of the cell are the mechanical scribing or the wet chemical etching process. Both methods are in terms of speed and waste, keyword:

High contamination during wet etching, not practical.

Therefore, the laser process is ideal for selective, non-contact removal of the coating.

Advantages of Laser Contact Opening

- Interdigitated Back Contact Solar Cells (IBC) have comb-like interlocked metal contacts on the back side. Also interdigitated under the contacts are the doped emitter and back surface field regions.

- The challenges in fabricating this cell structure lie in precisely defining the n+ and p+ doped regions on the backside and avoiding short circuits when contacting the two regions separately.

- High-precision laser systems from InnoLas Solutions achieve the necessary precision of the local contact opening (significantly smaller than 10µm) with maximum throughput of up to 7,500 wafers per hour.

Recommended machine type: LUMION, ULTAGO