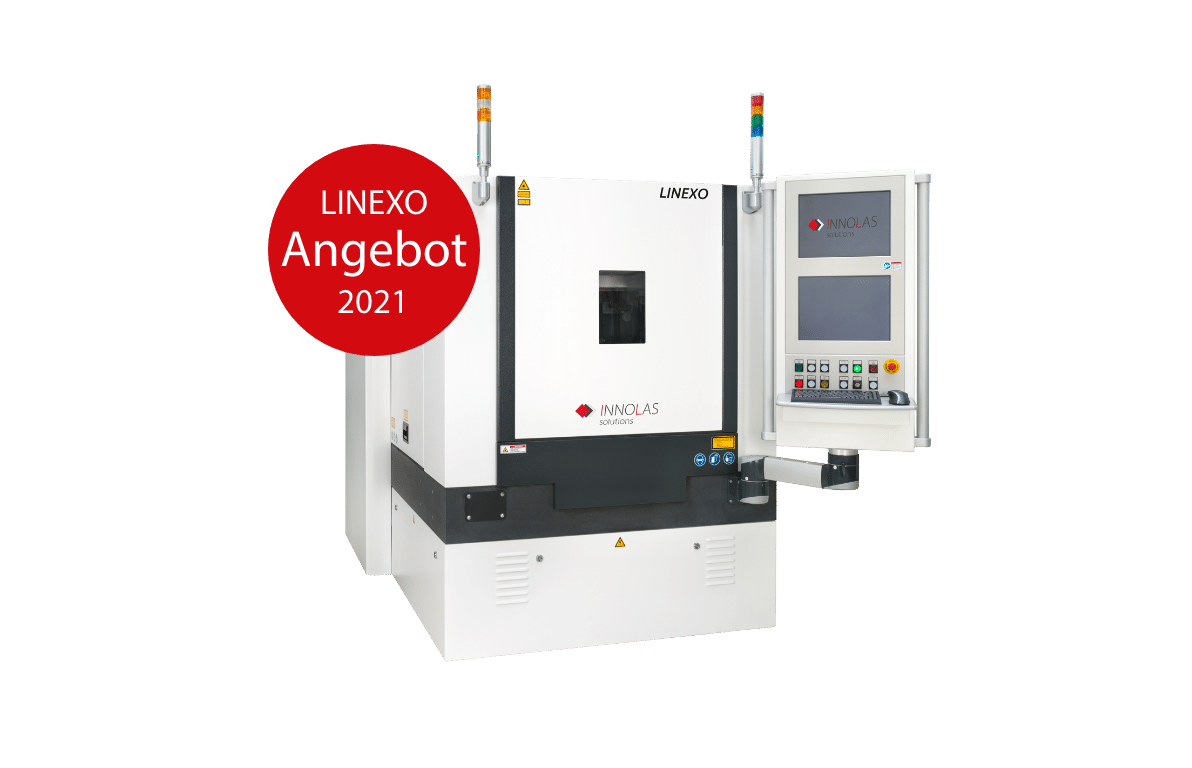

Unser einmaliges Angebot für Sie:

- LINEXO Single Head mit Vollausstattung zum Aktionspreis

- Garantierte Lieferung noch im Dezember 2021

Unser einmaliges Angebot für Sie – LINEXO Single Head Picosekunden-Lasermaschine mit Vollausstattung

Zur Productronica in München haben Sie die einmalige Chance: Sie bekommen unseren hochklassigen LINEXO Single Head Laser mit Vollausstattung und unserer “Pulse-on-Demand”-Technologie zum Sonderpreis!

Dieses Angebot gilt nur für ein einziges Modell – sichern Sie es sich also gleich. Die Lieferung erfolgt garantiert noch im Dezember. Nutzen Sie die momentan gebotenen staatlichen Fördermittel für US-Fertiger oder investieren Sie Ihr Restbudget 2021.

LINEXO ist DIE Laser-Maschine für komplexe und kleinste Anwendungen – vom Laserbohren bis zum Nutzentrennen von Leiterplatten: Weil sie besonders genau arbeitet und immer absolut konstante Pulsenergie an die empfindlichen Materialien abgibt. Die präzisen Prozesse des Lasers schonen Ihre Materialien und erzeugen Prozessqualitäten, die Sie mit herkömmlichen Lasern nicht erreichen. Die LINEXO ist besonders langlebig und es fallen so gut wie keine Wartungskosten an.

Die beste Laser-Anlage auf dem Markt:LINEXO Single Head Picosekunden-Lasermaschine

- Höchste Präzision: Unsere LINEXO ist +/- 5 μm genau und in der Wiederholung sogar 2 μm – somit das genaueste System am Markt

- Pulse-on-Demand: Der grüne Pikosekundenlaser setzt sehr kurze Pulse ab – und zwar abhängig von der Geschwindigkeit. Das schafft einzigartig exakte Ergebnisse.

- Beim Pico Laser verdampfen die gelaserten Materialien, statt zu schmelzen. Der Abtrag ist kalt und nicht heiß wie bei normalen Lasern. So vermeiden Sie Materialschäden.

- Die genaue Arbeit des Lasers führt dazu, dass sich Materialschichten nicht unerwünscht ablösen.

- Profitieren Sie von geringen Folgekosten: Andere Maschinen auf dem Markt haben Wartungsgebühren von durchschnittlich 20.000 Euro im Jahr. Die Laserquellen der LINEXO sind langjährig stabil.

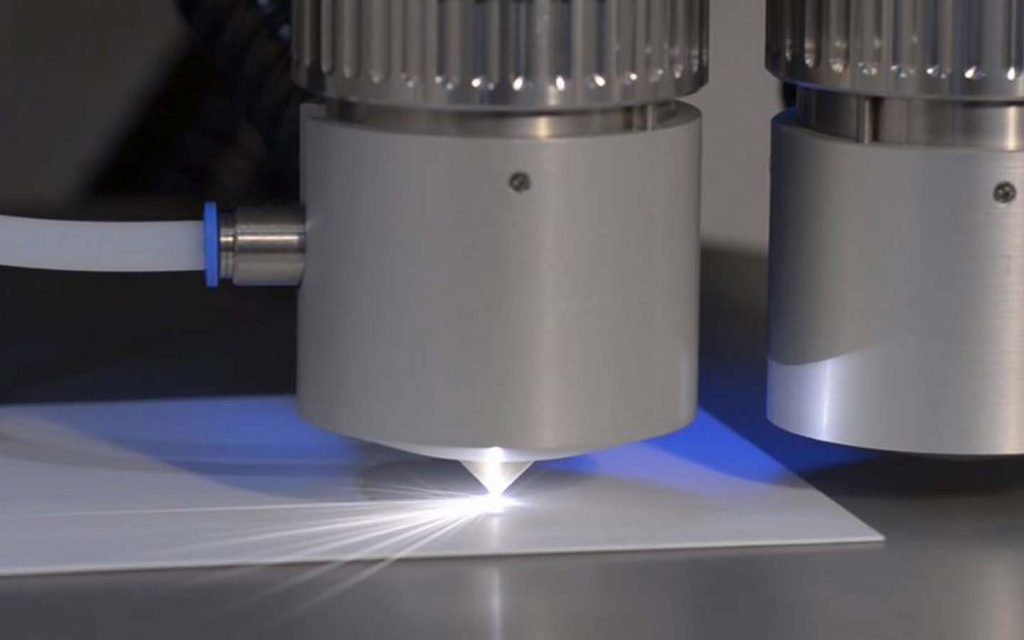

Konventionelle Laser: Breiter Schnittkanal durch verlangsamten Scanner aber voller Laserfrequenz.

Best Laser Pulse Prozess: Perfekte Qualität durch absolut konstanten Energieeintrag.

Die LINEXO ist einzigartig auf dem Markt!

Konventionelle Laser haben immer die gleichen Probleme: Die Laserpulse werden im gleichen Rhythmus auf das Material gesendet und sind in der Pulsfrequenz nicht flexibel. Der Laserprozess beschleunigt am Anfang einer Laserstruktur und wird am Ende langsamer. Darauf sind konventionelle Laser nicht angepasst. Die Laserpulse kommen im gleichen Rhythmus weiter und treffen auf das Material. Dadurch verbrennen die empfindlichen Materialien, die der Laser schneidet. Um das zu korrigieren, verlangsamen Betriebe ihre Laseranlagen. Aber auch das führt zu unbefriedigenden Ergebnissen, denn die Pulse in der Mitte des Prozesses sind nun zu weit auseinander und schneiden das Material nicht richtig. Die goldene Mitte zu treffen, ist mit konventionellen Lasern so gut wie unmöglich.

Best Laser Pulse Prozess der LINEXO macht den Unterschied

Erleben Sie den großen Unterschied der LINEXO. Die Laserpulse bleiben durchgehend im korrekten Abstand. Das schafft nur die LINEXO durch ihre ideal ausgeklügelte Kombination aus Laser und Scanner: Die LINEXO steuert die Pulse des Lasers abhängig von der Geschwindigkeit des Lasers auf dem Material – in Echtzeit. So erhalten Sie einen absolut konstanten Energieeintrag. Das macht den Prozess unempfindlich und stabil und sorgt für perfekte Qualität.

Der Prozess ist für den Nutzer der LINEXO deswegen viel sicherer: Das Material verbrennt nicht und die Schnitte sitzen richtig. So ist die Qualität der Produkte durchgehend perfekt.

Best Laser Pulse Prozess

Die LINEXO steuert die Pulse des Lasers abhängig von der Geschwindigkeit des Lasers auf dem Material – in Echtzeit. So erhalten Sie einen absolut konstanten Energieeintrag. Das macht den Prozess unempfindlich und stabil und sorgt für perfekte Qualität.

Welche Anwendungen bietet die LINEXO?

Die LINEXO ist eine Multi-Purpose-Anlage, die sich für eine Vielzahl an Laser-Aufgaben eignet. Nutzen Sie sie für:

- Laser Drilling

- Laser Depaneling

- Laser Scribing

- Laser Ablation

Auch in Bezug auf die Materialien sind Sie mit LINEXO flexibel: Setzen Sie den Laser bei Keramik, Metall und Silizium sowie für Rigid und Flex PCBs ein.

Haben Sie Fragen zu den vielfältigen Anwendungsmöglichkeiten der LINEXO? Wir sind gerne für Sie da.

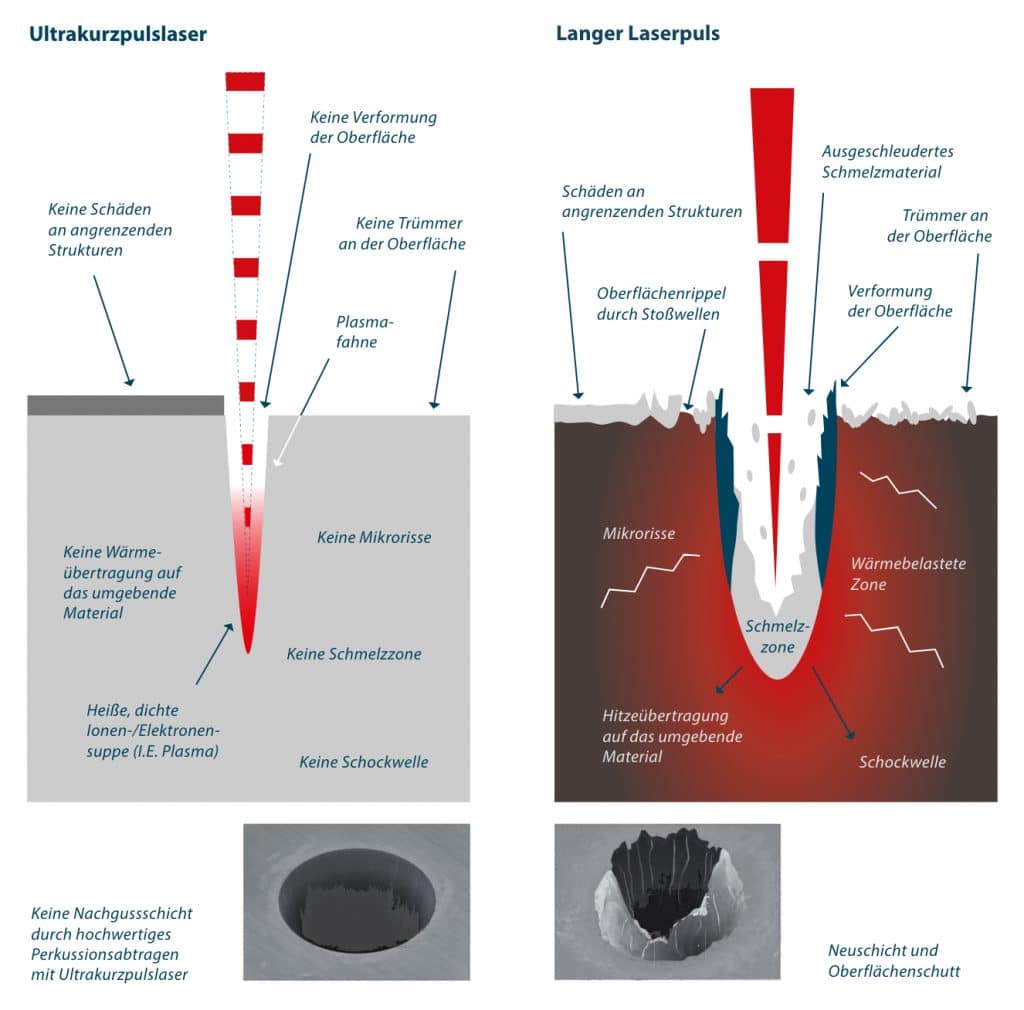

Warum ein grüner Pico Laser so besonders ist im Gegensatz zu anderen Laserquellen?

Pikosekunden-Laserpulse sind 1 Million Mal kürzer als die Pulse eines typischen CO2 Lasers, weshalb die Energie in einem kürzeren Zeitrahmen komprimiert wird (15 Megawatt Pulse Peak Power) – so werden extrem hohe Pulsenergien erzeigt.

Die wärmebeeinflusste Zone eines Pikosekundenlasers ist im Vergleich zu den Nanosekunden- oder CO2– Lasers aufgrund des kälteren Abtrags viel kleiner.

Materialverdampfung statt Schmelzen vermeidet eine Oberflächenbeschädigung neben dem Bohrloch und dem Material.

Die Stoßwellen der Laserpulse werden beim grünen Picoloaser abgeschwächt. So kommt es nicht zu Schäden am Material wie Delaminierung von Zwischen- und Decklagenkupfer.

Kompatibel und flexibel

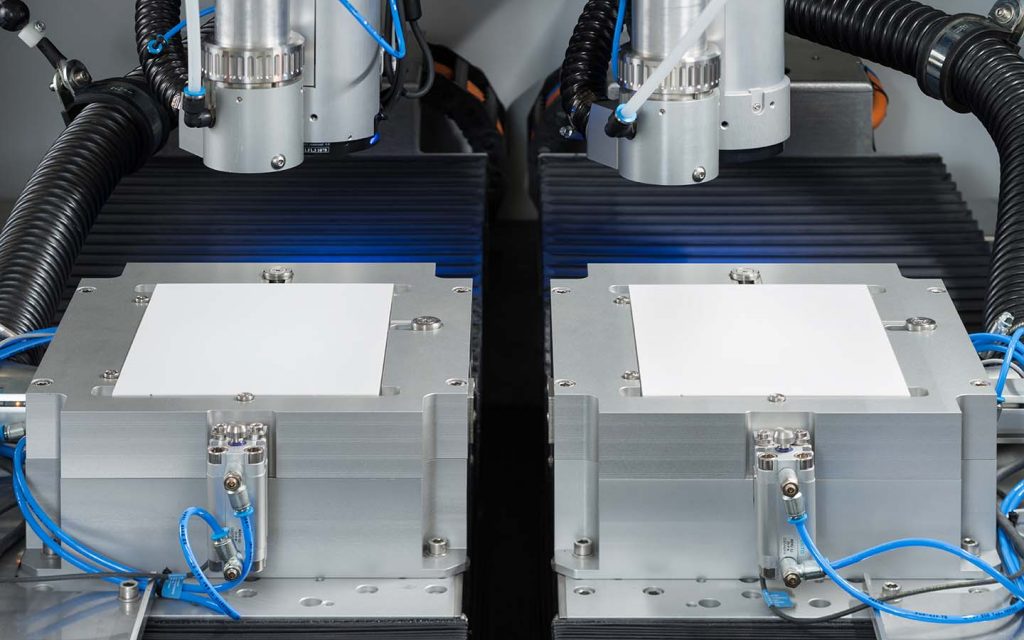

Die LINEXO ist eine Stand Alone Maschine: Sie können Sie also bereits im jetzigen Zustand für Ihre Zwecke einsetzen. Allerdings sind auch viele Erweiterungen möglich. Zusätzliche Automatisierungen sind sofort, aber auch im Nachgang möglich – so arbeiten Sie noch effektiver.

Erweitern Sie den angebotenen Picosekundenlaser bei Bedarf:

Ein Dual Head mit bis zu drei Quellen ist möglich.

Weitere Informationen und das Datenblatt finden Sie hier